-

Product DescriptionCompany Info.<>

- Model:

- ZZYVP-16B

- Processing customization:

- Yes

- Material:

- Stainless steel

- Connection form:

- Flange

- Nominal diameter:

- DN15-150 mm

- Applicable medium:

- Nitrogen gas

- Pressure environment:

- High pressure

- Operating temperature:

- Normal temperature

- Flow direction:

- One-way

- Driving mode:

- Pneumatic

- Parts and accessories:

- Actuator

- Form:

- Plunger type

- Types:

- Straight-through type

- Standard:

- National standard

- Sealing form:

- Soft seal type

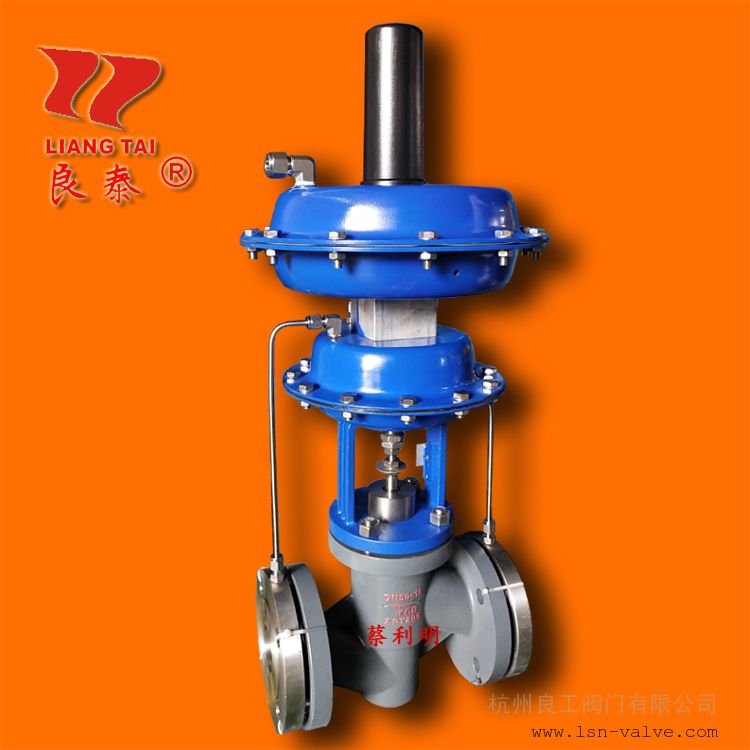

ZZYVP-16B nitrogen seal pressure reducing valve

Application:

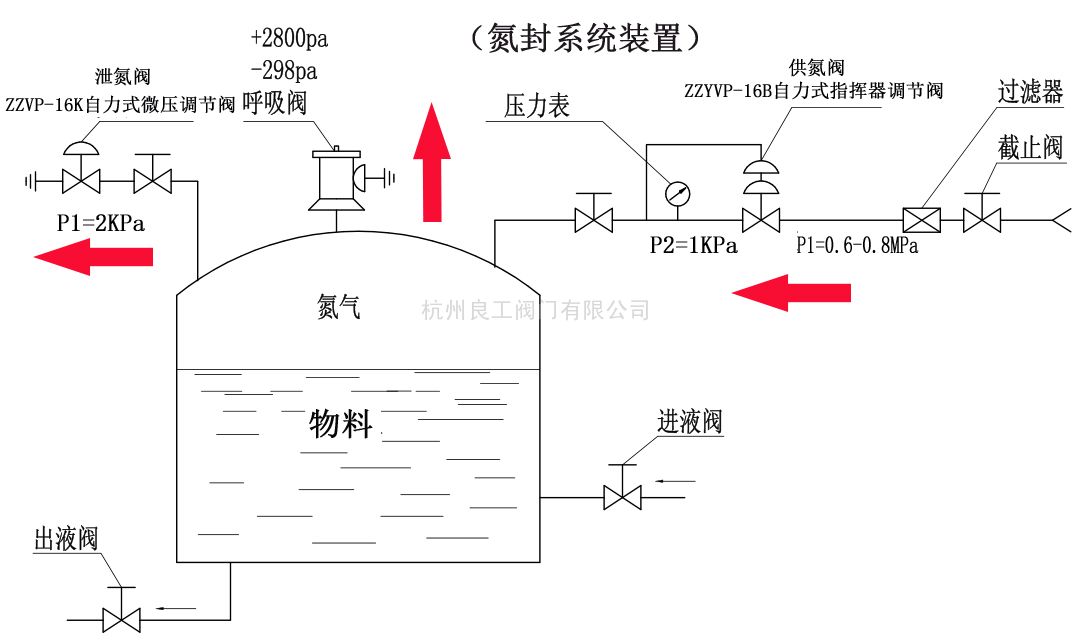

Nitrogen seal pressure relief valve system of the tank The nitrogen seal system consisting of (nitrogen supply valve, nitrogen vent valve) and safety valve (safety vent valve) ensures that the headspace of the tank is under inert air protection and atmospheric pressure control.

ZZYVP-16B nitrogen seal pressure reducing valve(namely with a commander operation type self-pressure regulating valve) by the actuator, ordinary body stainless steel and anti-fluorine actuator and straight through single-seat fluorine lined bellows valve components. Because the valve contact medium parts are high-pressure injection molding process, lined with corrosion resistance, aging resistance polyethylene propylene (referred to as F46), but also the use of PTFE bellows seal, so the valve is widely used in chemical, petroleum, metallurgy, pharmaceutical, electric power and other industries on acid, alkali strong corrosion medium and toxic, volatile gas, liquid medium process control.

Product Description:ZZYVP-16B nitrogen seal pressure relief valve is a self-contained micro-pressure control system independently developed and developed by our factory. It is mainly used to keep the pressure of protective gas (usually nitrogen) at the top of the container constant, so as to avoid direct contact between the materials in the container and the air, prevent the materials from volatilizing, being oxidized, and the safety of the container. This product has the characteristics of energy-saving, sensitive action, reliable operation, convenient operation and maintenance. Widely used in petroleum, chemical and other industries.

Product Features:

Corrosion resistance: the valve body cavity, valve core, valve seat, valve stem are 316 stainless steel, acid, alkali, strong corrosion resistance.

◆ Good sealing performance: double sealing with PTFE bellows and packing to ensure no leakage.

Little leakage: Since the valve core and valve seat are soft seals, the leakage is lower than the national IV standard.

◆ Adopt light and small multi-spring actuator, small size, light weight, high adjustment accuracy.

◆ No additional energy, can work in no electricity, no gas occasions, both convenient, but also save energy, reduce costs;

◆ The pressure of nitrogen supply valve is easy to set, which can be carried out under the condition of continuous production;

◆ Nitrogen valve pressure detection diaphragm effective area is large, set spring stiffness is small, sensitive action, device works smoothly;

◆ No packing design, valve stem by small friction, rapid response, high control accuracy;

◆ Nitrogen supply valve is operated by commander, pressure reduction ratio can reach 100:1, pressure reduction effect is good, control accuracy is high;

◆ To ensure the safety of the tank, it is necessary to set a breather valve on the top of the tank;

◆ Breathing valve only plays a safety role, avoiding the defects of frequent opening and closing in conventional nitrogen sealing devices.

Working principle of nitrogen seal:

A completenitrogen seal device consists of two parts: nitrogen supply device and nitrogen discharge device. The nitrogen supply device consists of a director and a main valve, and the nitrogen release device consists of an internal feedback pressure-opening micro-pressure regulating valve. Nitrogen pressure is generally set to 100 mmH2O. Precise control is achieved by nitrogen sealing devices.When the liquid inlet valve of the storage tank is opened and materials are added into the tank, the liquid level rises, the volume of the gas phase part decreases and the pressure rises; when the pressure in the tank rises to the pressure set point of the nitrogen release device, the nitrogen release device opens and releases nitrogen to the outside, so that the pressure in the tank drops. When the pressure drops to the pressure set point of the nitrogen release device, the nitrogen release device automatically closes.

When the liquid outlet valve of the storage tank is opened and the user discharges the material, the liquid level drops, the volume of the gas phase part increases, the pressure in the tank decreases, the nitrogen supply device is opened, nitrogen is injected into the storage tank to increase the pressure in the tank, and the nitrogen supply device is automatically closed when the pressure in the tank rises to the level of nitrogen supply.

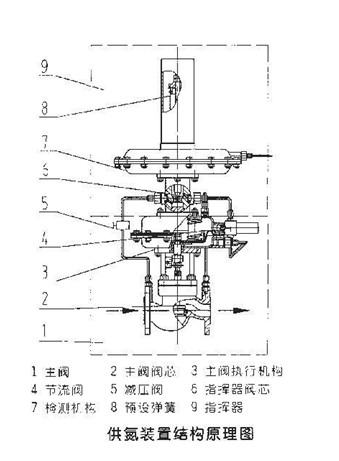

Working status of nitrogen sealing valve of nitrogen supply device:

The structure of nitrogen supply device is shown in the figure below. The medium at the pressure point on the top of the tank is introduced into the detection mechanism (7) through the pressure guide pipe. The medium generates a force on the detection element to balance with the spring (8) and the pre-tightening force. when the pressure in the tank is reduced to be lower than the pressure set point of the nitrogen supply device, the balance is destroyed, so that the valve core (6) of the pilot is opened, so that the gas in front of the valve enters the upper and lower film chambers of the main valve actuator (3) through the pressure reducing valve (5) and the throttle valve (4), and the main valve core (2) is opened to fill nitrogen into the tank; When the pressure in the tank rises to the pressure set point of the nitrogen supply device, due to the preset spring force, the valve core (6) of the closing command device closes the main valve due to the spring action in the main valve actuator, and the nitrogen supply is stopped. Description:

Description:

◆ Generally, the nitrogen pressure is between 3× 10^5-10× 10^5Pa.

◆ Tank top breathing valve only plays a safety role, is in the main valve failure, resulting in too high or too low pressure in the tank, play a safety role, under normal circumstances do not work

◇ Nitrogen relief valve installed on the top of the tank, the diameter is generally consistent with the diameter of the liquid inlet valve

◆ Generally, the pressure set point of the nitrogen release valve is slightly higher than the pressure set point of the nitrogen supply valve, so as to avoid frequent operation of the nitrogen supply and release devices, waste nitrogen and affect the service life of the equipment.

◆ If the user working conditions and modeling manual is different, please contact the technical development department of our factory to negotiate and solve.Benefits:

1. Pressure setting is realized on the commander, so it is convenient, fast, time-saving and can be continuously set under operating conditions.

2, the control accuracy is about 1 times higher than ZZY type self-operated, so it is suitable for use in situations with high control accuracy.

3, for the same valve, the adjustment range is wider than ZZY type self-operated.

Main technical parameters and performance indicators:

Nominal diameter DN(mm) 20 25 40 50 80 100 150

Seat diameter DN(mm) 6 15 20 25 32 40 50 65 80 100 125 150

Rated flow coefficient Kv 3.2 5 8 10 20 32 50 80 100 160 250 400

Pressure regulating range Kpa 0.5~70 20~120 60~400 300~700 500~1000

Nominal pressure PN(Mpa) 1.0 1.6

Temperature of conditioned medium (℃) 80 200flow characteristic

Adjustment accuracy ( %)≤ 5

Allowable pressure drop (Mpa) 1.6 1.6 1.1 0.6 0.4

Effective area of actuator film (C㎡) 200 280 400

Allowable leakage: conform to ANSI B16.104— 1976 Class IV

Selection of flow characteristics of regulating valve:

At present, the inherent flow characteristics of existing control valves mainly include: straight line, equal percentage, parabola and quick opening, among which the first two are common. Linear flow characteristics refer to the flow rate and opening of the regulating valve proportional relationship. Equal percentage flow characteristic means that the percentage of flow change of the regulator valve is equal over the full stroke. Linear flow characteristics in the small opening, the relative flow changes greatly, strong adjustment, easy to produce overshoot, causing vibration, and in the opening, the relative flow changes small, weak adjustment, not sensitive enough. Equal percentage flow characteristics of the flow rate change percentage is equal, in a larger opening range, the relative flow rate change is large, the adjustment sensitivity is effective, the equal percentage characteristic curve is always below the linear characteristic curve, in the same opening, the flow rate is smaller than the linear characteristic, and because the equal percentage characteristics of the flow concentrated in the large opening area, considering the same opening deviation margin, the required flow coefficient margin is large. Therefore, the capacity of the valve with equal percentage flow characteristics is smaller than that of the linear flow characteristics.

Control valve flow and loss characteristics improvement measures:

The maximum value of the relative lift of the regulating valve under rated conditions should be increased, which helps to significantly increase the flow efficiency. When the regulating valve is fully open, the relative lift should be maintained at more than 40%. For example, if the pressure ratio is 0.98, the relative lift can be increased from 31.2% to 54.2%, and the total pressure loss coefficient can be reduced from 1.896 to 0.873. The reduction amplitude is maintained at 51%.

The cavity area in the lower part of the butterfly valve will affect the flow area, which will make the effective flow area decrease continuously and affect the actual flow level. The part close to the valve disc in the valve flow field is the area with large aerodynamic loss, accounting for about 67% of the whole loss. When the lift is small, it reaches more than 82%. When the lift is small, if the pressure ratio of the inlet and outlet is less than 0.8, shock waves will occur at the tail of the annular passage, bringing very serious total pressure loss.

In a word, numerical simulation of three-dimensional flow field performance of control valve, study of distribution law of flow loss, elaboration of factors affecting flow level, study of loss characteristics of control valve in many aspects, such as local and global, have high accuracy.

ZZYVP-16B with a director regulating nitrogen sealing valve

1, nitrogen sealing valve and nitrogen relief valve are micro-pressure regulating valve is not allowed to the whole valve pressure test. If pressure test of pipeline is required, nitrogen sealing valve shall be removed and replaced by pipeline or bypass shall be opened.

2, such as nitrogen sealing valve before the valve, valve after the manual stop valve is installed. When starting the nitrogen sealing valve, first open the stop valve behind the nitrogen sealing valve, and then open the stop valve in front of the nitrogen sealing valve (when opening the stop valve in front of the nitrogen sealing valve, it should be opened slowly to prevent the instantaneous pressure in front of the nitrogen sealing valve from being too large, causing damage to the actuator). If the nitrogen seal valve is damaged during operation, it will not be covered by the warranty.

Nitrogen seal valve selection points:

1, regulating function ① requires stable valve action;② small opening adjustment performance is good;③ select the required flow characteristics;④ meet the adjustable ratio; 5 small resistance, large flow ratio (valve rated flow parameters and nominal diameter ratio); 6 regulating speed.

2, leakage and cut-off pressure difference This is inseparable, interrelated two factors. Leakage should meet the process requirements, and there are protective measures for the reliability of the sealing surface; the cut-off pressure difference (the pressure difference when the valve is closed) must be proposed (unfortunately, many design institutes do not have this parameter in the control valve calculation specifications), so that the selected valve has sufficient output force to overcome it, otherwise it will lead to the actuator selection.

Even if it is a clean medium, there is also a problem of blocking, which is that impurities in the pipeline are brought into the control valve by the medium, causing blocking, which is a common fault, so the anti-blocking performance of the valve should be considered. Generally angular stroke type control valve than straight stroke type control valve anti-blocking performance is good.

4, corrosion resistance It includes erosion resistance, cavitation, corrosion. It mainly involves the selection of materials and the service life of the valve. At the same time, it involves economic issues. The essence of this problem should be that the selected valve has good corrosion resistance and reasonable price. If you can choose lining fluorine valve, you should not choose full corrosion resistant alloy valve; you can choose angle high pressure valve with good anti-cavitation effect and simple structure (to meet the service life of about two years), you should not choose other high pressure valves with complex structure and expensive price.

5, pressure and temperature resistance This involves the control of large nominal pressure, the selection of working temperature. Pressure, if only high pressure is not difficult, mainly the pressure difference will produce cavitation; temperature resistance, usually solve the following 450 degrees is very easy, 450-600 degrees is not difficult, but to 600 degrees or more, the contradiction will be prominent; when the temperature is 120 degrees when the selection of soft sealing materials for the shutoff control valve is usually not desirable, hard seal cutoff should be considered.

6, weight and appearance This problem is very intuitive, must be a good appearance, light weight valve welcomed by the user manufacturers. Here is to change a bias that the control valve is a big thick, heavy or poor appearance. It's nothing. Now we attach great importance to it, thus proposing that the control valve should have the characteristics of miniaturization, light weight and instrumentation.

- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.