-

Product DescriptionCompany Info.<>

- Model:

- ZZYP-16B

- Processing customization:

- Yes

- Material:

- Carbon steel

- Connection form:

- Flange

- Nominal diameter:

- DN15-300 mm

- Applicable medium:

- Steam

- Pressure environment:

- High pressure

- Operating temperature:

- High temperature

- Flow direction:

- One-way

- Driving mode:

- Steam

- Parts and accessories:

- Actuator

- Form:

- Plunger type

- Types:

- Straight-through type

- Standard:

- National standard

- Sealing form:

- Hard sealed type

I. Product introduction:

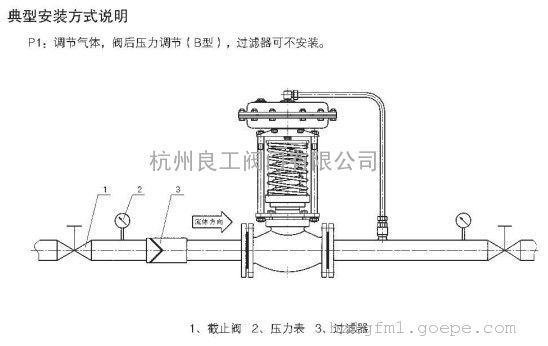

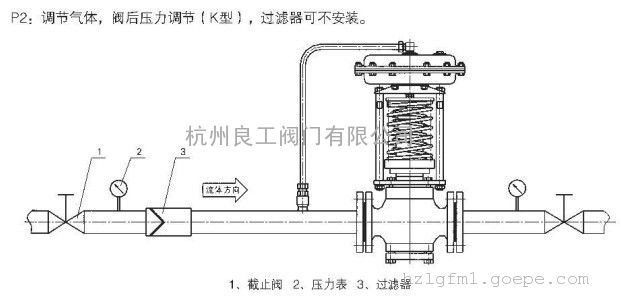

ZZYP-16B high temperature self-operated steam pressure relief valvewithout external energy, the use of regulated medium energy as a power source into the actuator to control the position of the spool, change the pressure difference and flow at both ends, so that the valve before (or after the valve) pressure stability. It has the advantages of sensitive action, good sealing performance, small fluctuation of pressure set point, etc. It is widely used in automatic control of gas, liquid and steam medium decompression and stabilization or pressure relief and stabilization. This series of products have single seat (ZZYP), sleeve (ZZYM), double seat (ZZYN), three kinds of structure; the actuator has two kinds of membrane type, piston type; the action type has pressure regulation after the valve for pressure reduction (B type) and pressure regulation before the valve for pressure relief (K type). The nominal pressure class of the product is PN16, 40 and 64; the diameter range of the valve body is DN20~300; the leakage class is II, IV and VI; the flow characteristic is fast opening; the pressure is adjusted from 15 to 2500Kpa. Can be combined as required to meet the requirements of user conditions.II. Working principle:ZZYP -16B high temperature self-operated steam pressure reducing valve is used to regulate the medium flow, pressure and level. According to the adjustment position signal, automatically control the opening of the valve, so as to achieve the adjustment of medium flow, pressure and liquid level.Pressure regulator valve depends on the pressure and temperature of the medium flowing through the valve itself as an energy source to drive the valve to work automatically, without the need for external power supply and secondary instruments. This kind of self-operated regulating valve uses the feedback signal (pressure, pressure difference, temperature) of the valve output end to be transmitted to the actuator through the signal pipe to drive the valve flap to change the opening degree of the valve, so as to adjust the pressure, flow and temperature. This control valve is divided into direct action and indirect action of two types.

Pressure relief valve B type direct action type is also known as spring load type, its structure has elastic elements such as: spring, bellows, bellows type temperature package, etc., using elastic force and feedback signal balance principle.

Indirect acting valve rear steam pressure regulating valve ZZYP-16B closed type, adding a director (pilot valve) it plays an amplification role in feedback signals and then through the actuator, driving the main valve clack movement to achieve the purpose of changing valve opening. In the case of a pressure regulating valve, the feedback signal is the outlet pressure of the valve, which is introduced into the actuator through the signal pipe. If it is a flow control valve, there is an orifice plate (or other resistance device) at the outlet of the valve. The differential pressure signal is taken out from both ends of the orifice plate and introduced into the actuator. If it is a temperature regulating valve, the outlet of the valve has a temperature sensor (or temperature package) to drive the actuator through the thermal expansion and contraction of the medium in the temperature sensor.

III. Determination of pressure adjustment range:

Pressure adjustment range is segmented, see main parameters and performance index table, control pressure should be selected near the middle value of adjustment range as far as possible.

Fourth, the valve pressure regulating valve, the relationship between the valve pressure and the valve pressure:

It is a regulating system itself, and the valve itself has certain pressure drop requirements. For the pressure regulating valve (B type) after the valve, in order to ensure that the pressure after the valve is within a certain range, the pressure before the valve must reach a certain value.

V. Determination of the mode of action of the whole machine:

Pre-valve pressure regulating valve (K type) its initial position of the spool in the closed position, when the pre-valve pressure gradually increased, the valve gradually opened until the pre-valve pressure stabilized at the required given value.

The valve core in its initial position is in the open position. When the valve pressure gradually increases, the valve gradually closes until the valve pressure stabilizes at the required given value.

VI. Product features:

◆ No additional energy, can work in places without electricity and gas, both convenient and energy-saving.

◆ The pressure segmentation range is fine and cross each other, and the adjustment accuracy is high.

◆ Pressure setpoint can be set continuously during operation.

◆ For valve pressure regulation, the ratio of valve pressure to valve pressure can be 10:1~10:8.

◆ Rubber diaphragm type detection, high precision and sensitive action of actuator.

◆ Pressure balance mechanism is adopted to make the regulating valve responsive and accurate.

VII. Installation instructions:

ZZYP-16B closed typesteam pressure regulating valve iswidely used in petroleum, chemical industry, electric power, metallurgy, food, textile, machinery manufacturing and civil buildings and other industrial equipment, can be applied to gas, liquid, steam medium pressure reduction and stabilization (valve regulation) or pressure relief and stabilization (valve regulation), but because it uses the pressure of the medium itself to operate the actuator, the actuator is filled with medium, so the installation method should be matched with this.

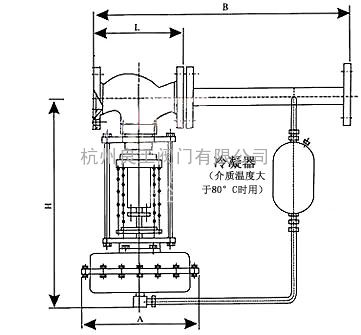

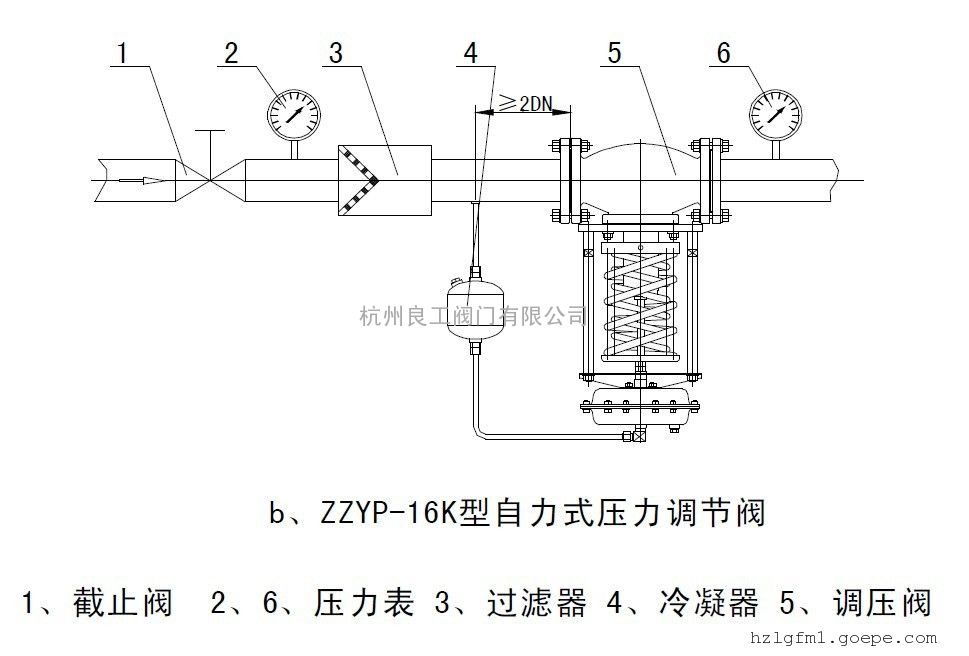

ZZYP-16B self-operated steam desuperheating and pressure-reducing regulating valveshall be installed at the appropriate position away from the pressure regulating valve. The pressure-opening pressure regulating valve shall be larger than 2 times the pipe diameter, and the pressure-closing pressure regulating valve shall be larger than 6 times the pipe diameter. When installing the condenser, pay attention to the position of the condenser, so that it is higher than the film head and lower than the process pipeline to ensure that the condenser is filled with condensate.VIII. Material of main parts:

◆ Valve body: ZG230-450, ZG1Cr18Ni9Ti, ZGCr18Ni12Mo2Ti

◆ Valve core: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

◆ Valve seat: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

◇ Valve stem: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

Cover: A3, A3 steel coated tetrafluoroethylene stainless steel

◆ Filler: B, F, oil resistant rubber

Nine, the use of methods and daily maintenance:self-pressure regulating valve boiler steam pressure automatic regulating valve pipeline should generally be installed horizontally.

How to use:

1. Operation when gas or low viscosity liquid is used at normal temperature:

( 1) slowly open the valve before and after the stop valve;

( 2) Loosen vent plug until gas or liquid escapes from actuator

(3) Then re-tighten the exhaust plug, and the regulating valve can work. The required pressure value can be obtained by adjusting the pressure regulating disc. When adjusting, observe the pressure indication value. The action shall be slow and the valve stem shall not rotate with it.

2. Operation when steam is used:

( 1) Unscrew the lower drain screw from the condenser

( 2) Loosen the actuator exhaust plug.

( 3) Use the drain to add through the injection port until the exhaust hole flows out.

( 4) Tighten the exhaust plug and continue to fill the water until it overflows the injection port.

( 5) Tighten the filler screw

( 6) Slowly open the front and rear stop valves of the regulating valve.

(7) Adjust the pressure regulating disc and observe the pressure gauge until the value reaches the requirements.

Maintenance:

After put into operation, general maintenance work is very little, usually just observe whether the pressure indication before and after the valve meets the requirements of the process. In addition, observe whether the packing box and actuator leakage, if leakage should be tightened or replaced packing and diaphragm.

X. Common troubleshooting:

The pressure before the valve does not rise and always acts below the demand value?

Causes:

1 , set spring stiffness is too small

2 . The valve core is stuck by foreign matter;

3 . Valve stem and push rod are stuck;

4 , valve core, valve seat damage, leakage is too large 5, valve diameter is too large

Exclusion methods;

1 . Replace the spring

2 . Reassemble

3 . Readjustment

4 , re-grinding or replacement

5 . Replace smaller caliber

XI. Material selection of key valve components:

Safety valves are usually artificially part of the pressure vessel or pressure system they protect, and careful consideration must be given to the selection of materials for safety valves. In particular, for pressure-retaining and pressure-bearing parts, the selection of materials must comply with the requirements of specifications and standards. The main pressure-retaining or pressure-bearing component of the safety valve is the valve body, and the bonnet and bolts connecting the valve body and bonnet are also considered to be part of the pressure-retaining housing of the safety valve, so the pressure vessel specification also has material requirements for the bonnet and connecting bolts. Failure of these components may result in leakage of pressure, high temperature media or chemicals.

Factors affecting material selection for safety valve components include:

Pressure, temperature, corrosive medium or environment, relevant application specifications and standards.

Selection of materials for key components:

Certain parts of the safety valve are particularly critical to the safe operation and function of the flash. These components can be grouped into the following categories:

Pressure retaining component: A component that maintains inlet pressure (body) or outlet pressure (bonnet), including body bonnet attachment bolts.

Long-term liquid contact parts: parts in contact with the medium for a long time and maintain the tightness of the valve.

Guide component: provides disc to nozzle guidance and ensures stem movement up and down at all times.

Spring: Provides force to close valve.

Bellows (balanced design only): Provides backpressure compensation and/or corrosion protection for guide parts and springs.

Hangzhou Lianggong Valve Co., Ltd. production and sales: ZZYP-16B self-operated steam desuperheating and pressure reducing valve, self-operated steam pressure reducing valve, self-operated steam regulating valve and other steam special series pressure regulating valve.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.