-

Product DescriptionCompany Info.<>

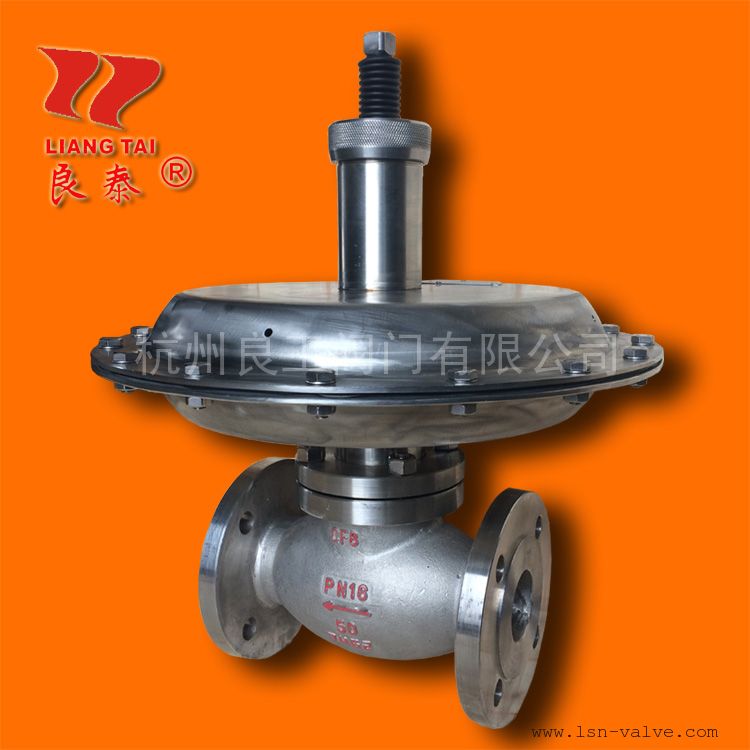

- Model:

- ZZYVP-16B

- Processing customization:

- Yes

- Material:

- Stainless steel

- Connection form:

- Flange

- Nominal diameter:

- DN15-100 mm

- Applicable medium:

- Nitrogen gas

- Pressure environment:

- High pressure

- Operating temperature:

- Normal temperature

- Flow direction:

- One-way

- Driving mode:

- Pneumatic

- Parts and accessories:

- Actuator

- Form:

- Plunger type

- Types:

- Straight-through type

- Standard:

- National standard

- Sealing form:

- Soft seal type

First, nitrogen seal valve selection parameters:

1. Nominal diameter DN(mm) of sputum supply and nitrogen discharge device

2. Name of medium

3. Nominal pressure PN(MPa) of nitrogen supply valve and nitrogen discharge valve

4. Working pressure and adjustment range

5. Rated flow coefficient Kv of sputum supply and nitrogen discharge device

6. Body, trim and packing materials

7. Inherent flow characteristics of sputum supply and nitrogen discharge devices

8. Device name and model

9. Pressure set point of sputum supply and nitrogen discharge device

Second, the difference between nitrogen sealed micro-pressure valve and differential pressure valve

1. The main control parameters of differential pressure valve are: nominal diameter, design nominal pressure, allowable temperature range of medium, control accuracy, etc.

2. For variable flow water system, install self-operated pressure difference control valve at the position where two points require constant pressure difference, which can eliminate the interference caused by flow adjustment by internal users of the controlled system, and also eliminate the interference of external network pressure fluctuation on the controlled system, so that the controlled system operates under stable conditions to ensure the quality of heating (air conditioning) and energy saving. nbsp;

3. In a dynamically controlled pipe network system, such as a variable flow system at the end, a self-operated differential pressure control valve should be set to ensure that the controlled system always works normally under the rated differential pressure. nbsp;

4, variable flow system horizontal branch, main pipe inlet and in the installation of temperature control valves or regulating valves and other dynamic systems branch, main pipe inlet, the installation of self-pressure differential control valve can be controlled loop supply, return water pipe pressure difference between constant.

5, should be in accordance with the flow and working pressure range to select the self-operated differential pressure control valve (note: because most products working pressure range is relatively narrow, if beyond the working range, it will lose control), and should not be directly in accordance with the pipe diameter to select the valve specifications.

6. Indoor heating is a metering and charging system with double pipe system, and the thermal inlet should be equipped with a self-operated pressure difference control valve. The differential pressure at both ends should not be greater than 100kPa and should not be less than 8kPa.

7. If the actual working pressure difference of the differential pressure control valve exceeds the working pressure difference range of the product, other adjustment equipment such as the one used should be used for initial adjustment.

8, usually self-operated differential pressure control valve does not have a shutoff function, need to add a shutoff valve.

9, pay attention to prevent impurities in the water blocking the capillary and membrane box parts of the valve, if necessary, set up a water filter before the valve.

Third, product characteristics:

1. The nitrogen supply device is operated by a commander, with a pressure reduction ratio of 100:1, good pressure reduction effect and high control accuracy;

2. In order to ensure the safety of the tank, a breather valve needs to be set on the top of the tank;

3, breathing valve only plays a safety role, avoiding the defects of frequent opening and closing in the conventional nitrogen sealing device.

4, no additional energy, can work in no electricity, no gas occasions, both convenient, but also save energy, reduce costs;

5, pressure setting is convenient, can be carried out under the conditions of continuous production;

6, force detection diaphragm effective area is large, set spring stiffness is small, action is sensitive, the device works smoothly;

7, the use of non-packing design, valve stem by small friction, rapid response, high control accuracy;IV. Application of structural decomposition of nitrogen sealing system:

ZZYVP-16B self-operated commander micro-pressure regulating valvestructure decomposition role is to prevent volatile toxic or combustible gas tank to the outside of the tank hazard safety, to maintain a certain micro-pressure nitrogen in the tank pressure, nitrogen sealing valve is located on the top of the tank. The medium at the pressure taking point is introduced into the detection mechanism through the pressure guide pipe. The design of the feedback structure enables the medium to directly enter the detection mechanism through the valve cover. The tank breather valve on the tank top can play a safety role. Generally, the pressure setting point of the nitrogen relief valve is slightly higher than that of the nitrogen supply valve, so as to avoid frequent operation of the nitrogen supply and relief devices. In terms of flow control, each valve is equipped with a fixed plate hole to control the percentage of flow. The size of each valve in the gas sealing system is arranged according to the gas flow table, and the flow rate suitable for the specific gas sealing is calculated according to the stable gas pressure provided. Nitrogen sealing valve in the nitrogen can play a replacement device medium, balance system pressure and other functions, used to maintain the top of the container protective gas pressure constant, the general nitrogen pressure is atmospheric, the main role is to reduce volatility, such as benzene tank, the second is to prevent the reaction of the medium and air, such as alkali tank. The inlet pressure is generally reduced to 1 bar. Suitable for all kinds of large storage tank gas seal protection system, reliable operation, and widely used in petroleum, chemical and other industries.

Breather valves should be installed at the highest point of the tank air supply to reduce material evaporation losses and ensure that direct and large passages for tank breathing are provided. For vertical tanks, the valve should be installed in the center of the tank top as far as possible. For tanks with insulation layer on the tank top, it can be installed near the ladder platform. When two breather valves are required, they shall be symmetrically arranged with respect to the center of the tank top. If the breather valve is used on the nitrogen sealing tank, the connecting pipe of nitrogen gas supply pipe shall be far away from the valve interface, and inserted into the storage tank about 200mm from the top of the tank, so that nitrogen gas will not be discharged directly after entering the tank, so as to achieve the purpose of nitrogen sealing.

V. Productinstallation and daily maintenance:

1. Installation:

(1)ZZYVP-16B self-operated pilot micro-pressure regulating valve before installation, check whether the whole machine parts are defective or loose, the pipeline should be cleaned, the medium flow direction should be consistent with the valve body arrow direction.

(2) In order to facilitate on-site maintenance and operation, appropriate space should be reserved around the valve.

(3) The valve should be installed vertically on the horizontal pipeline, the flange connection between the valve body and the pipeline, pay attention to the axial degree, and should be installed in the environment where the temperature does not exceed-25 ° C.

2. Use of nitrogen sealing valve

(1) Open the stop valve in front of the valve, so that the medium slowly flows into the valve body.

(2) Unscrew the pilot shield and loosen the pilot adjusting screw.

(3) Adjust the main spring of the commander to make the pressure behind the valve reach the set value.

(4) Fix the adjusting screw of the commander, install the shield, and the pressure regulating valve can start to work.

(5) When not in use, close the stop valve before the valve.

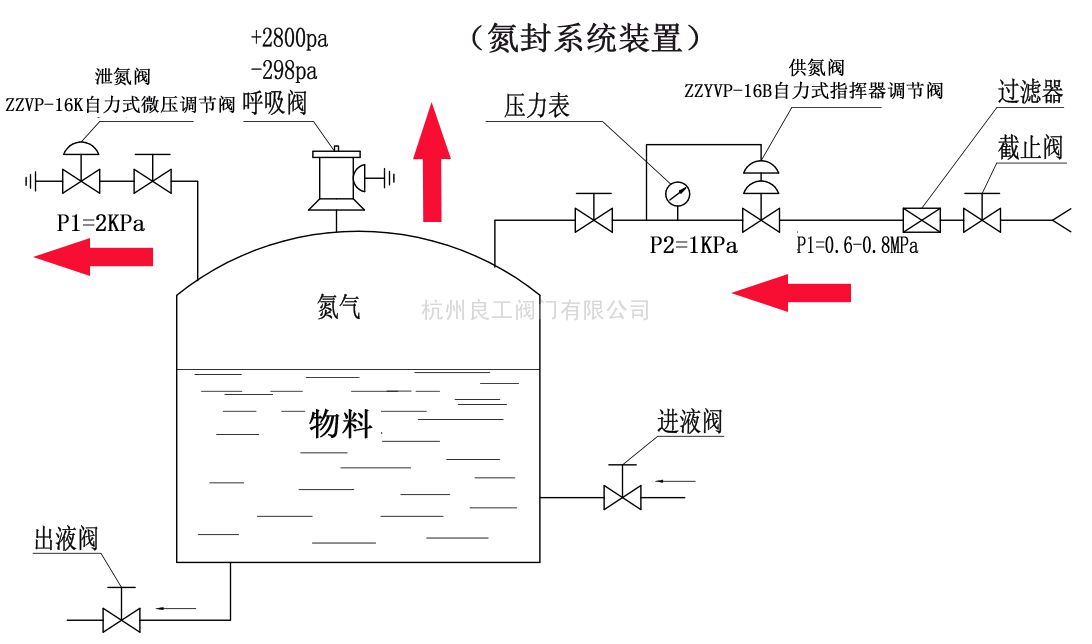

VI. Schematic diagram of nitrogen sealing valve system installation:1, working principle:

Tank nitrogen protection device nitrogen seal valve nitrogen valve schematic diagram, the upper end of the finished liquid in the tank covered with nitrogen (role: to prevent liquid products in the tank, volatile liquid, etc. from directly contacting the air, avoid volatilization, deterioration, ensure quality), through the nitrogen seal device control, can be more convenient to achieve this function.

When the material outlet valve is opened to discharge liquid, the liquid level in the tank drops, the volume of gas phase increases, and the nitrogen pressure drops below the set value. At this time, the LGR-81 nitrogen supply valve opens to supplement nitrogen into the tank to increase the pressure in the tank to the set value, and the LGR-81 nitrogen supply valve closes automatically. Similarly, when the liquid inlet valve is opened, the liquid level rises, the volume of gas phase decreases, and the nitrogen pressure rises. If the pressure exceeds the set value, the LGR-71 nitrogen relief valve will automatically open for pressure relief until the pressure drops to the set value, and the LGR-71 nitrogen relief valve will automatically close.

2. Features:

(1) Nitrogen supply pressure is convenient to set, and can be set without stopping production;

(2) Wide setting range of nitrogen pressure: from 0.35KPa to 1.5KPa

3. Valve parameters:

(1) ZZYVP-16B nitrogen supply valve front pressure 0.4MPa, nitrogen seal pressure 0.35KPa

(2) ZZVP-16K nitrogen relief valve set pressure before the valve 1.2KPa, after the valve vent,

VII. Main technical parameters and performance indicators:

Nominal diameter DN(mm) 20 25 40 50 80 100 150

Seat diameter DN(mm) 6 15 20 25 32 40 50 65 80 100 125 150

Rated flow coefficient Kv 3.2 5 8 10 20 32 50 80 100 160 250 400

Pressure regulating range Kpa 0.5~70 20~120 60~400 300~700 500~1000

Nominal pressure PN(Mpa) 1.0 1.6

Temperature of conditioned medium (℃) 80 200

flow characteristic

Adjustment accuracy ( %)≤ 5

Allowable pressure drop (Mpa) 1.6 1.6 1.1 0.6 0.4

Effective area of actuator film (C㎡) 200 280 400

Allowable leakage: conform to ANSI B16.104— 1976 Class IV

Eight, nitrogen sealing valve nitrogen supply valve nitrogen release valve actual display diagram:- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.