-

Product DescriptionCompany Info.<>

- Model:

- ZZYP-16B

- Processing customization:

- Yes

- Material:

- Carbon steel

- Connection form:

- Flange

- Nominal diameter:

- DN150 mm

- Applicable medium:

- Steam

- Pressure environment:

- High pressure

- Operating temperature:

- High temperature

- Flow direction:

- One-way

- Driving mode:

- Steam

- Parts and accessories:

- Actuator

- Form:

- Plunger type

- Types:

- Two-way type

- Standard:

- National standard

- Sealing form:

- Hard sealed type

I. Working principle:

ZZYP-16B self-operated steam pressure regulator iswidely used in industry. It is a kind of control device that can automatically adjust the pressure, temperature or flow theory of the measured medium without external resources. It is an energy-saving instrument with multi-function instrument control system such as control execution. Its types can be divided into self-pressure regulating valve, self-pressure differential pressure regulating valve, self-temperature regulating valve, self-steam pressure regulating valve. It is suitable for the occasions without power supply and automatic control.

II. Product introduction:

ZZYP-16B self-operated steam pressure regulating valve doesnot need external energy, uses the energy of the regulated medium as the power source to introduce the actuator to control the position of the spool, changes the pressure difference and flow at both ends, and stabilizes the pressure before (or after) the valve. It has the advantages of sensitive action, good sealing performance, small fluctuation of pressure set point, etc. It is widely used in automatic control of gas, liquid and steam medium decompression and stabilization or pressure relief and stabilization.

This series of products have single seat (ZZYP), sleeve (ZZYM), double seat (ZZYN), three kinds of structure; the actuator has two kinds of membrane type, piston type; the action type has pressure regulation after the valve for pressure reduction (B type) and pressure regulation before the valve for pressure relief (K type). The nominal pressure class of the product is PN16, 40 and 64; the diameter range of the valve body is DN20~300; the leakage class is II, IV and VI; the flow characteristic is fast opening; the pressure is adjusted from 15 to 2500Kpa. Can be combined as required to meet the requirements of user conditions.

Third, product characteristics:

◆ZZYN-16B self-operated pressure regulating valve does not need additional energy, can work in places without electricity and gas, both convenient and energy-saving.

◆ The pressure segmentation range is fine and cross each other, and the adjustment accuracy is high.

◆ Pressure setpoint can be set continuously during operation.

◆ZZYP-16B self-operated pressure-reducing and pressure-stabilizing device regulates the pressure after the valve, and the ratio of the pressure before the valve to the pressure after the valve can be 10:1~10:8.

◆ Rubber diaphragm type detection, high precision and sensitive action of actuator.

◆ Pressure balance mechanism is adopted to make the regulating valve responsive and accurate.

IV.Determination of pressure adjustment range:

Pressure adjustment range is segmented, see main parameters and performance index table, control pressure should be selected near the middle value of adjustment range as far as possible.

The relationship between the pressure before the valve and the pressure after the valve is as follows:

The self-operated regulating valve itself is a regulating system, and the valve itself has certain pressure drop requirements. For the post-valve pressure regulating valve (Type B), in order to ensure that the post-valve pressure is within a certain range, the pre-valve pressure must reach a certain value.

V.Determination of the mode of action of the whole machine:

Pre-valve pressure regulating valve (K type) its initial position of the spool in the closed position, when the pre-valve pressure gradually increased, the valve gradually opened until the pre-valve pressure stabilized at the required given value.

The valve core in its initial position is in the open position. When the valve pressure gradually increases, the valve gradually closes until the valve pressure stabilizes at the required given value.

VI. Installation method:

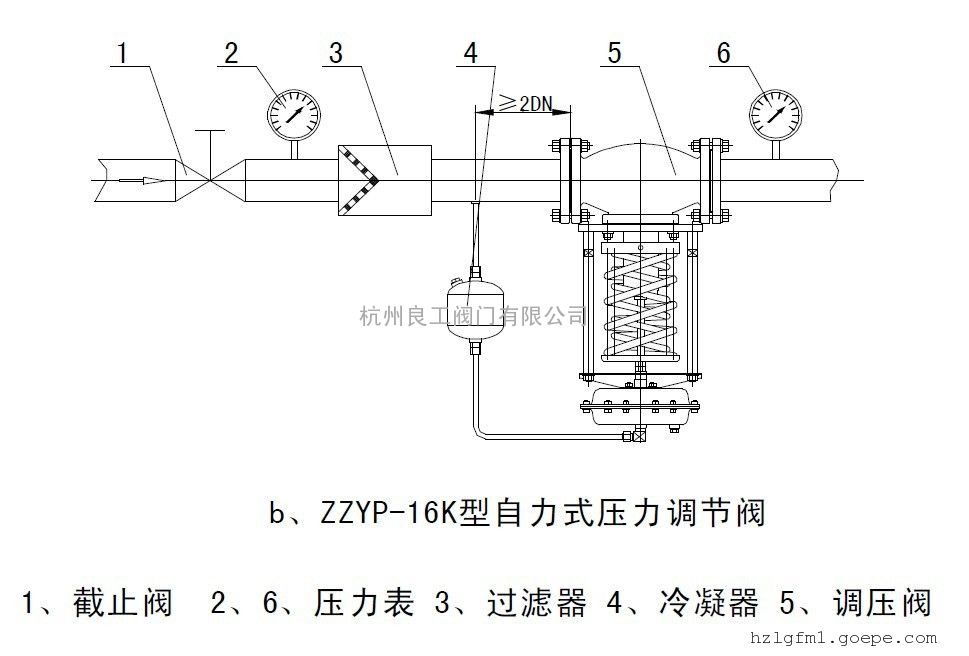

ZZYPM-16B self-operated steam temperature and pressure regulating valveis widely used in petroleum, chemical industry, electric power, metallurgy, food, textile, machinery manufacturing and civil buildings and other industrial equipment, can be applied to gas, liquid, steam medium pressure relief (valve regulation) or pressure relief (valve regulation), but because it uses the pressure of the medium itself to operate the actuator, the actuator is filled with media, so the installation method should be matched with this.

The pressure point shall be set at the appropriate position away from the pressure regulating valve during installation. The pressure opening pressure regulating valve shall be larger than 2 times the pipe diameter, and the pressure closing pressure regulating valve shall be larger than 6 times the pipe diameter.

When installing the condenser, pay attention to the position of the condenser, so that it is higher than the film head and lower than the process pipeline to ensure that the condenser is filled with condensate.VII. Main parts and materials:

◇ Valve stem: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

◇ Membrane cover: A3, A3 steel coated tetrafluoroethylene stainless steel

◆ Filler: B, F, oil resistant rubber

◆ Valve body: ZG230-450, ZG1Cr18Ni9Ti, ZGCr18Ni12Mo2Ti

◆ Valve core: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

VIII.Connection standards:

Flange standard: casting method according to BG9113-88, JB/79-94

Flange sealing surface type: PN16 convex

◇ PN40, 64 is concave and convex, valve body is concave

◆ Structure length according to BG12221-98

IX. Please provide the following information when ordering:

◇ Name and model of regulating valve

◆ Nominal diameter (mm)

◆ Nominal pressure (Mpa)

◇ Pressure before and after valve

◆ Operating temperature and range

◆ Whole machine mode of action

◇ Body, trim and packing materials

◆ Accessories

◇ Valve full flange standard

Rated flow coefficient (Kv)

◇ Inherent flow characteristics

Media name and status

Other special requirementstechnical parameters Main technical parameters and performance indicators

Nominal diameter DN(mm)

20

25

32

40

50

65

80

100

125

150

200

250

300

Rated flow coefficient (KV)

7

11

20

30

48

75

120

190

300

480

760

1100

1750

Rated stroke (mm)

8

10

14

20

25

40

50

60

70

Nominal pressure PN(Mpa)

1.6、4.0、6.4

Pressure regulation range (MP a)

15~50 40~80 60~100 80~140 120~180 160~220 200~260

240~300 280~350 330~400 380~450 430~500 480~560 540~620

600~700 680~800 780~900 880~1000 980~1500 1000~2500Flow characteristics (℃)

quick-opening

Adjustment accuracy (%)

±5

Operating temperature (℃)

≤350

leakage allowed

Hard Seal (1/h)

Single seat: 10 - 4 valve rated capacity (Class IV); Double seat, sleeve: 5 10 - 3 valve rated capacity (Class II)

Soft seal (m1/h)

0.15

0.30

0.45

0.60

0.90

1.7

4.0

6.75

11.10

16.0

pressure reducing ratio

* Large

10

* Small

1.25

Hangzhou Lianggong Valve Co., Ltd. long-term supporting EPS foam machinery equipment GIQ-10W pneumatic high vacuum butterfly valve, pneumatic shut-off ball valve, proportional valve, EPS foam machine steam pressure relief valve ZZYN-16B self-operated pressure regulating valve, pressure relief valve, automatic pressure regulating ZZYPM-16BW self-operated steam relief valve, etc.

Main features:1. The machine adopts PLC programmable controller and computer touch screen to complete the automatic cycle process of mold opening and closing, feeding, heating, insulation, cooling, demoulding, product ejection, etc.

2. Vacuum system is mainly composed of vacuum storage tank, vacuum condensation tank and high efficiency water circulation vacuum pump.

3.& This machine adopts foreign advanced EPS vacuum penetration heating and pulse heating molding technology developed by our company, which has strong penetration ability, fast plate forming, good adhesion and low steam consumption to ensure the consistency of inside and outside products. Cooling vacuum cooling technology greatly shortens the molding cycle, each foam plate production cycle of 4-6 minutes, can adapt to the production of 6-40kg/m3 foam plastic plate, plate thickness up to 1 meter.

4. The control instruments, electric and pneumatic components, various valves and other accessories used by the machine are all domestic and foreign high-quality brand-name products.

5. The machine adopts centralized control of hydraulic station and differential control of hydraulic control system. Make the plate machine open and close the mold action fast and orderly, so as to ensure that the machine runs smoothly, safely and reliably.

6. The machine is welded with high-quality section steel, and each template has been aged and heat treated. Make the machine high strength, no deformation, can withstand the expansion force of high density products.

7. The surface of the machine cavity is coated with Teflon (optional for customers), and the plate is easy to demould;

8. Thickening vacuum sheet forming machine equipped with automatic conveying device and automatic electronic weighing (optional for customers);

Different working principles of different types of self-operated regulating valves

Depending on the pressure and temperature of the medium flowing through the valve itself, the valve is driven to work automatically without external power supply and secondary instruments. This kind of self-operated regulating valve uses the feedback signal (pressure, pressure difference, temperature) of the valve output end to be transmitted to the actuator through the signal pipe to drive the valve flap to change the opening degree of the valve, so as to adjust the pressure, flow and temperature. This control valve is divided into direct action and indirect action of two types.

The direct action type is also called spring load type, and its structure has elastic elements such as spring, bellows, bellows type temperature package, etc., using the principle of elastic force and feedback signal balance.

Indirect action control valve, adding a director (pilot valve) it plays an amplification role in the feedback signal and then through the actuator, driving the main valve flap movement to change the valve opening.

In the case of a pressure regulating valve, the feedback signal is the outlet pressure of the valve, which is introduced into the actuator through the signal pipe.

If it is a flow control valve, there is an orifice plate (or other resistance device) at the outlet of the valve. The differential pressure signal is taken out from both ends of the orifice plate and introduced into the actuator.

If it is a temperature regulating valve, the outlet of the valve has a temperature sensor (or temperature package) to drive the actuator through the thermal expansion and contraction of the medium in the temperature sensor.

Self-operated control valve is used to adjust the process parameters such as medium flow, pressure, temperature and liquid level in the field of industrial automation process control. According to the control signal in the automation system, the opening of the valve is automatically adjusted to realize the adjustment of medium flow, pressure, temperature and liquid level.

How to select self-operated differential pressure control valve

(1) Self-operated differential pressure control valve should be matched with the differential pressure of the pipe network outside the valve.

The differential pressure control valve operating characteristic curve is different with different differential pressure of pipe network outside the valve. Therefore, in the design selection and actual operation of the pipe network, it should be ensured that the pipe and pipe network pressure difference at the valve installation point changes within the allowable range of the valve. The actual pressure difference is too large or too small will make the spring failure, resulting in the valve can not work properly.

(2)Self-operated differential pressure control valveset pressure differential should match the resistance of the valve piping system at the design flow rate to ensure that the valve works in its best working area. Too large a difference between the two will lead to excessive actual flow of the pipeline system inside the valve, resulting in hydraulic imbalance of the pipeline system outside the valve or causing the actual flow of the pipeline system inside the valve to be too small to affect the heating effect.(3) Self-operated differential pressure control valve should be matched with the differential pressure of the pipe network outside the valve.

The differential pressure control valve operating characteristic curve is different with different differential pressure of pipe network outside the valve. Therefore, in the design selection and actual operation of the pipe network, it should be ensured that the pipe and pipe network pressure difference at the valve installation point changes within the allowable range of the valve. The actual pressure difference is too large or too small will make the spring failure, resulting in the valve can not work properly.

(4)Selection of Caliber of Self-operated Differential Pressure Control Valve

Different caliber differential pressure control valve control flow range is different. When selecting valves, the design flow of the pipeline system in the valve should be taken according to the valve operating characteristic curve in the best working area of the valve control flow range. Select the valve diameter is too small, so that the valve in its control flow range of high-end work, easy to produce noise. Select the valve diameter is too large, so that the valve in its control flow range of the low end of the work, the system flow range is too large, easy to cause hydraulic imbalance of the pipeline system outside the valve, but also cause economic waste. General valve diameter than the valve pipeline system interface diameter equal or small a better.

- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.