-

Product DescriptionCompany Info.<>

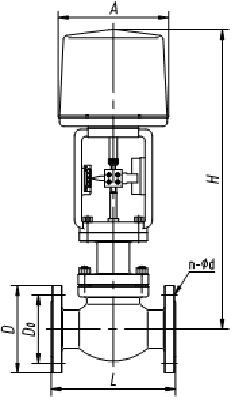

- Model:

- ZDLP-16P

- Processing customization:

- Yes

- Material:

- Stainless steel

- Connection form:

- Flange

- Nominal diameter:

- DN50 mm

- Pressure environment:

- High pressure

- Operating temperature:

- High temperature

- Flow direction:

- One-way

- Driving mode:

- Electron

- Parts and accessories:

- Actuator

- Form:

- Plunger type

- Types:

- Straight-through type

- Standard:

- National standard

- Sealing form:

- Soft seal type

I. Product introduction:

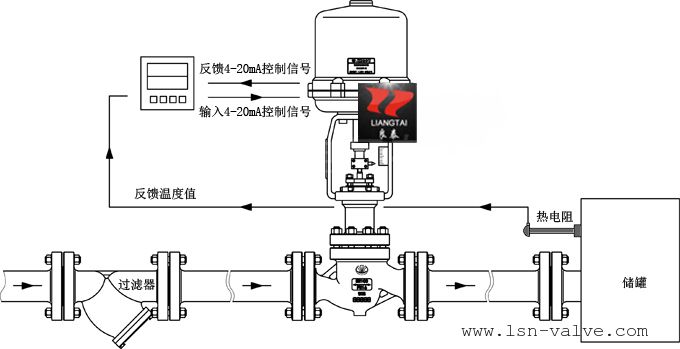

ZDLP-16P electric proportional small flow regulating valve receives DC current signal from regulating instrument, changes the regulated medium flow, and keeps the controlled process parameters at the given value. Widely used in power, metallurgy, chemical, petroleum, textile, pharmaceutical, paper and other industrial sectors of production automation control.

The nominal diameter of the product is from 20 to 200mm, the nominal pressure is 1.0, 1.6, 4.0, 6.4MPa, the service temperature range is from-40℃ to 450℃, and the acceptance signal is 0~10mA.DC or 4~20mA.DC. ZAZPE-16 electronic electric control valve electric single-seat type is suitable for small pressure difference, medium viscosity or slightly particulate impurities. ZAZPE-16 electronic electric control valve sleeve type is suitable for large pressure difference occasions. According to the valve trim seal part material points and metal-metal and non-metal-metal seal two kinds, the latter valve closed leakage can reach VI (zero leakage) standards. According to different packing can be divided into general packing seal and bellows seal two kinds, the former for general occasions, while the latter is used to important occasions that do not allow leakage. Flow characteristics are linear or equal percentages.

Different actuators can be divided into two types: ordinary type and electronic type. A wide variety of varietal sizes are available.Second, product application:

ZDLP-16P electric proportional small flow regulating valveis an important executive unit instrument in industrial automation process control. The square valve is a new type of material, with the increasing degree of automation in the industrial field, it is being more and more applied in various industrial production fields. Compared with the traditional pneumatic control valve, it has obvious advantages: electric control valve energy saving (only consumes electricity when working), environmental protection (no carbon emissions), quick and convenient installation (no complicated pneumatic pipeline and air pump workstation). According to the power used by the actuator, the valve is divided into linear characteristics, equal percentage characteristics and parabolic characteristics according to its function and characteristics. Desuperheating and decompression device is a kind of steam thermal energy parameter (pressure, temperature) conversion device and energy-saving device using waste heat widely used in thermal energy engineering in modern industry, such as cogeneration, central heating (or steam supply) and light industry, electric power, chemical industry, textile and other enterprises. Through this device, the steam parameters provided by users are reduced to the appropriate temperature and pressure required by users, so as to meet the requirements of users, and heat energy can be fully saved and heat energy can be reasonably used.Third, the selection of electric control valve points:

1, electric control valve selection of the main control parameters are: nominal diameter, design nominal pressure, medium allowable temperature range, flow coefficient, etc.

For strict occasions where the flow rate and opening height are directly proportional, special control valves should be selected. Ball valve and butterfly valve-general coarse adjustment can be selected.

3, the sealing performance of the valve is one of the main indicators to assess the quality of the valve. The sealing performance of the valve mainly includes two aspects, namely internal leakage and external leakage. Internal leakage refers to the sealing degree of the medium between the valve seat and the closing member. External leakage refers to leakage of stem packing, leakage of middle gasket and leakage of valve body due to casting defects. Leakage is not allowed to occur.

4, the ideal flow characteristics of electric control valve are fast open, parabolic, linear, etc. Four kinds of percentage, according to the actual working flow characteristics to choose a suitable flow characteristics of the control valve.

Note: S= pressure loss when the regulating valve is fully open/total pressure loss of the series branch where the regulating valve is located.

5, the nominal diameter of the control valve should be selected according to the required valve flow capacity to determine. Nominal diameter of regulating valve should not be too large or too small. Too large, increase engineering costs, and the valve is in a low percentage range, the adjustment accuracy is reduced, so that the control performance is deteriorated. Too small, increase the system resistance, even when the valve is 100% open, the system still can not reach the set capacity requirements.

6. Adjustment pressure difference and shutoff pressure difference of regulating valve

For regulating valve, its allowable regulating pressure difference and shut-off pressure difference are important indicators of its selection. If the actual pressure difference is higher than the allowable adjustment pressure difference of the regulating valve, the valve will not be adjusted accurately, and the valve actuator will be damaged seriously.

IV. Material of main parts:

◆ Valve body, valve cover: HT200, ZG230-450, ZG1Cr18Ni9Ti

◆ Valve core: ZG1Cr18Ni9Ti, stellite alloy surfacing reinforced PTFE

◆ Filler: PTFE, flexible graphite

◇ Push rod, bushing: 2Cr13

◆ Gasket: rubber asbestos sheet, 10, 1Cr18Ni9Ti asbestos spiral gasket

◆ Bellows: 1Cr18Ni9Ti

V. Product features:

◆ The regulating valve body is designed according to the principle of fluid mechanics, and the rated flow coefficient is increased by 30%.

◆ The adjustable range of the regulating valve is large, the inherent adjustable ratio is 50, and the flow characteristics are straight and equal percentages.

◆ Control valve shut-off type adopts soft seal structure valve core, up to VI leakage standard (zero leakage)

◆ The servo amplifier of the regulating valve adopts deep dynamic negative feedback, which can improve the automatic adjustment accuracy.

VI. Technical parameters:Nominal diameter DN(mm)(seat diameter dn) 20 25 32 40 50 65 80 100 125 150 200 (10) (12) (15) (20) rated flow coefficient straight stage 1.8 2.8 4.4 6.9 11 17.6 27.5 44 69 110 176 275 440 690 equal percentage 1.6 2.5 4 6.3 10 16 25 40 63 100 160 250 400 630 Rated stroke (mm) 16 25 40 60 Nominal pressure PN(MPa) 1.0 1.6 4.0 6.4 inherent flow characteristic straight line, equal percentage inherent adjustable ratio 50 leakage allowed single-seat Hard seal: Class IV Soft seal: Class VI sleeve Hard seal: Class II Soft seal: Class VI Operating temperature t(℃) -20~200 -40~250 -40~450 -60~450 Signal Range (mA.DC) 0~10 4~20 mode of action Electrically-closed electrically-open Operating ambient temperature (℃) Electric control valve: -20 °C to 70 ° C Servo amplifier: 0 ° C to 50 ° C Use ambient humidity Electric control valve: 95% Servo amplifier: 85% mains input 220V 50Hz 380V 50Hz 24AC/DC

The flow characteristics of the electric control valve is the relationship between the relative flow rate of the medium flowing through the electric control valve and its opening degree under the condition that the pressure difference between the two ends of the valve remains constant.The flow characteristics of electric control valve are: linear characteristics, equal percentage characteristics and parabolic characteristics of three kinds.

VII. Installation precautions:New design, installation of electric control valve control system, in order to ensure that the control valve can work normally when driving, and make the system safe operation, the new valve before installation, should first check whether the nameplate mark on the valve is consistent with the design requirements. The following items shall also be commissioned. Basic error limit; full stroke deviation; backlash; dead band; leakage (in strict cases). If the control valve in the original system has been overhauled, in addition to the calibration of the above items, the sealing inspection of the stuffing box and connection of the old valve should also be carried out. In field use, many are often not caused by the quality of the control valve itself, but by improper installation and use of the control valve, such as improper installation environment, installation position and direction, or because the pipeline is not clean. Therefore, the electric control valve in the installation and use to pay attention to the following aspects:

1, the regulating valve belongs to the field instrument, the environmental temperature should be in the range of-25 to 60 ℃, relative humidity≤ 95%. If it is installed in the open air or high temperature, waterproof and cooling measures should be taken. Keep away from vibration sources or increase anti-vibration measures where there are seismic sources.

2, the control valve should generally be installed vertically, under special circumstances can be tilted, such as tilt angle is very large or the valve itself is too heavy when the valve should increase the support protection.

3, the installation of regulating valve pipes generally do not leave the ground or floor too high, in the pipeline height is greater than 2 m should try to set the platform, in order to facilitate the operation of the handwheel and easy maintenance.

4. Clean the pipeline before installing the regulating valve to eliminate dirt and welding slag. After installation, in order to ensure that impurities do not remain in the valve body, the valve should be cleaned again, that is, all valves should be opened when the medium is introduced, so as not to get stuck with impurities. After using the handwheel mechanism, return to the original neutral position.

5, in order to make the control valve in the event of failure or maintenance of the production process can continue, the control valve should be added bypass pipeline.

At the same time, special attention should be paid to whether the installation position of the regulating valve meets the requirements of the process.

6, the electrical part of the electric control valve installation should be carried out according to the requirements of the relevant electrical equipment construction. If the explosion-proof products should be installed in accordance with the requirements of the Code for Installation of Electrical Equipment in Explosive Hazardous Places. If SBH type or other six-core or eight-core wires are used in the field, the outer diameter is?? 11.3 mm rubber mounting cable. In use and maintenance, it is strictly prohibited to open the cover for maintenance and pry the flameproof surface in explosive places. At the same time, do not knock or scratch the flameproof surface during disassembly, and restore to the original flameproof requirement state after maintenance.

7, the actuator reducer after repair should pay attention to refueling lubrication, low-speed motor generally do not disassemble oil. After assembly, check whether the valve position is consistent with the valve position opening indication.Hangzhou Liangsheng Electric Co., Ltd.(Hangzhou Lianggong Valve Co., Ltd.) produces electronic electric control valve, pneumatic diaphragm control valve, self-operated pressure control valve, nitrogen sealing device nitrogen sealing valve, self-operated steam pressure relief valve, pneumatic cut-off ball valve, pneumatic butterfly valve, etc.

- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2025 Goepe.com All rights reserved.