-

Product DescriptionCompany Info.<>

- Model:

- ZJHP-16P

- Processing customization:

- Yes

- Material:

- Stainless steel

- Connection form:

- Flange

- Nominal diameter:

- DN15~350 mm

- Pressure environment:

- High pressure

- Operating temperature:

- High temperature

- Flow direction:

- One-way

- Driving mode:

- Pneumatic

- Parts and accessories:

- Locator

- Form:

- Plunger type

- Types:

- Two-way type

- Standard:

- National standard

- Sealing form:

- Hard sealed type

I. Product overview:

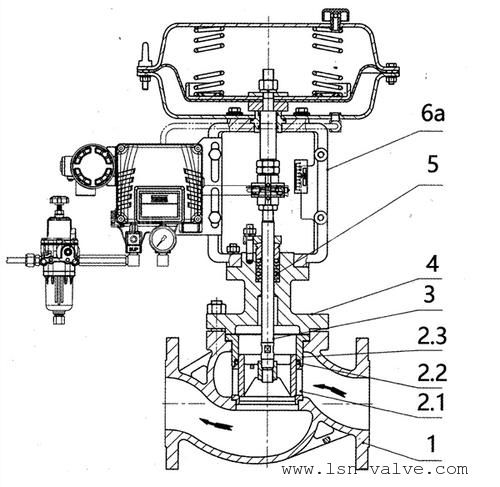

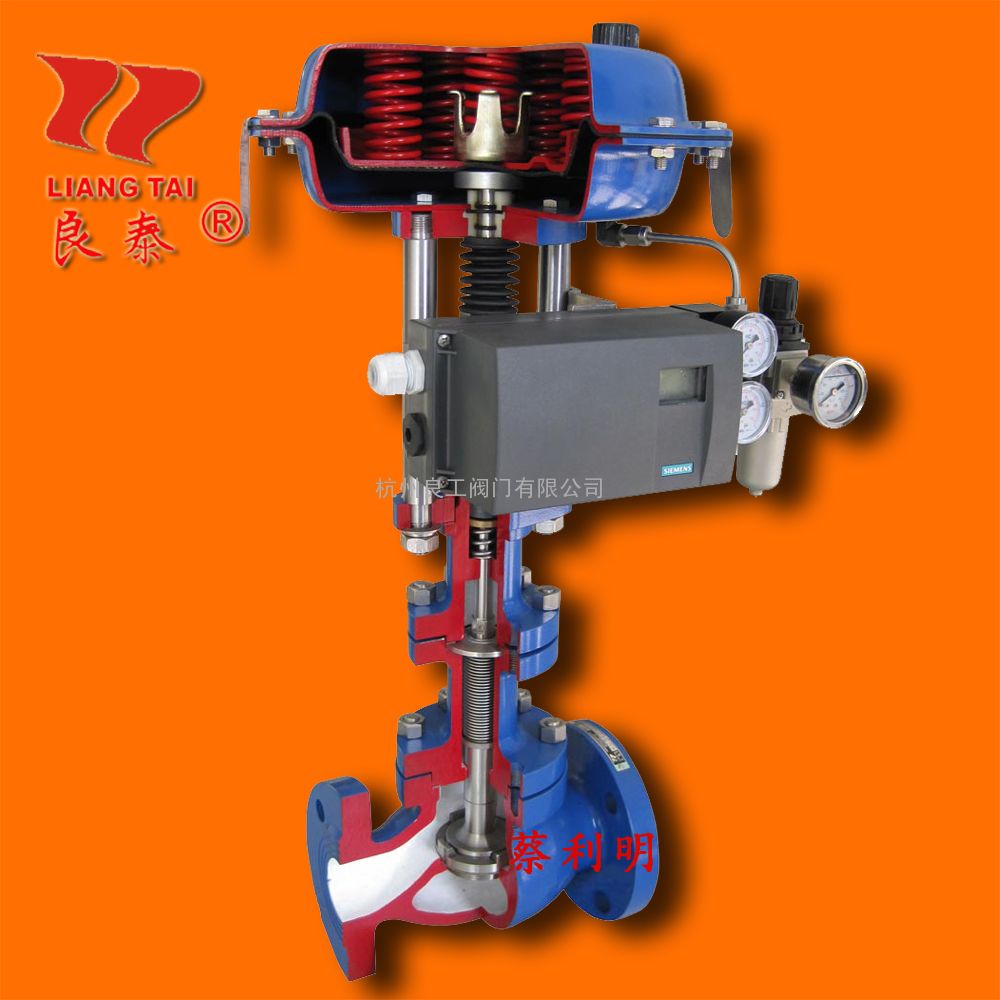

The ZJHP-16P plunger-type pneumatic diaphragm flow regulating valveuses compressed air as the power source, a cylinder as the actuator, and uses electrical valve positioners, converters, solenoid valves, position retaining valves and other accessories to drive the valve. Switch quantity or proportional adjustment, receiving control signals from industrial automation control systems to adjust various process parameters such as flow, pressure, and temperature of the pipeline medium. Pneumatic control valve is characterized by simple control, rapid response, and intrinsic safety, no need to take additional explosion-proof measures.

II. Uses and characteristics:

ZJHP-16P plunger pneumatic diaphragm flow control valveis a right-angle rotary structure, it is used with valve positioner, can achieve proportional adjustment; V valve core * is suitable for various adjustment occasions, with a rated flow coefficient, adjustable ratio, good sealing effect, sensitive adjustment performance, small size, vertical and horizontal installation. Suitable for controlling gas, steam, liquid and other media.

Pneumatic diaphragm control valve is a right-angle rotary structure, composed of V-type valve body, pneumatic actuator, positioner and other accessories; has an approximate equal percentage of the inherent flow characteristics; double bearing structure, starting torque is small, with excellent sensitivity and induction speed; super shear capacity.III. Application of working conditions:

The regulating valve adopts top-oriented structure and is equipped with multi-spring actuator. Pneumatic diaphragm single-seat control valve has the advantages of compact structure, light weight, sensitive action, S streamlined fluid channel, small pressure drop loss, large valve capacity, accurate flow characteristics, convenient disassembly and so on. Pneumatic diaphragm single-seat control valve is widely used in precise control of gas, liquid, steam and other media, process parameters such as pressure, flow, temperature, liquid level to maintain a given value. It is especially suitable for working occasions where the pressure difference between the front and rear of the valve is small and the leakage is small.

Control valve This series of products are adjustable type, adjustable cut-off type, bellows seal type, jacket insulation type and other varieties. Product nominal pressure grades PN10, 16, 40, 64; valve body diameter range DN20~200. Applicable fluid temperature range from-200℃~560℃ in a variety of grades. Leakage standards are Class IV or VI. Flow characteristics are linear or equal percentages. A wide variety of specifications are available.

IV. Structural advantages:

Top-oriented single-seat regulating valve, compact structure, few parts, easy maintenance. Metal spool suitable for a variety of working occasions, up to IV leakage standards, ZXPQ soft seal structure spool up to VI leakage standards. The valve body is designed as a low flow resistance flow channel with equal cross section according to the principle of fluid mechanics, and the rated flow coefficient is increased by 30%. The adjustable range is large, and the inherent adjustable ratio is 50. The actuator adopts multi-spring structure, which reduces height by 30% and weight by 30%.

V. Matters needing attention when selecting control valves under flash and scour conditions:

1. Flash evaporation and cavitation

In the regulating valve injection of liquid, often flash and cavitation two phenomena. Their occurrence not only affects the selection and calculation of caliber, but also causes serious noise, vibration, material damage, etc., which directly affects the service life of the control valve. Therefore, in the calculation and selection of valves, flash and cavitation are problems that cannot be ignored.

When the liquid with pressure P1 flows through the throttle hole, the flow velocity suddenly increases sharply, and the static pressure drops suddenly. When the pressure P2 behind the hole reaches or is lower than the saturated vapor pressure Pv of the fluid, part of the liquid will vaporize into gas, forming the phenomenon of gas-liquid two-phase coexistence. This phenomenon is called flash evaporation, which will erode and destroy the valve core and other materials, and affect the correctness of the liquid calculation formula, making the calculation complicated. If P2 does not remain below saturation vapor pressure after flash, it rises sharply after leaving the orifice, when bubbles are broken and converted to form cavities or bubbles, i.e. flash stage; these bubbles are broken in the second stage, i.e. cavitation stage.

After many bubbles concentrate in the orifice valve, the natural effect of the increase in flow, resulting in a blocking situation. Therefore, the calculation formulas of flash evaporation and cavitation must be different before and after.

After cavitation occurs, the bubble, which reaches critical size, begins to change into an elliptical shape due to pressure recovery and compression of the bubble by the elevated pressure. Then, upstream, the surface begins to flatten out and then suddenly bursts, all the energy concentrated at the point of rupture, creating alargeimpact force.

Flash and cavitation occur only in liquid media. One stage of cavitation is flash, where the outlet pressure of the valve remains below the saturated vapor pressure of the liquid, but erosion has occurred on the trim, where damage occurs due to high fluid velocity * near the line of contact between the spool and seat ring.After flash damage, the outer surface of the valve core has a wear mark. In the second stage of cavitation, the pressure after the valve rises above the saturated vapor pressure. Due to the sudden rupture of the bubble, all the energy is concentrated at the rupture point, resulting in alarge impact force, which can be as high as several thousand Newton, so it seriously collides with and destroys the valve core, valve seat and valve body. This action is like sand high-speed jet on the surface of the valve core, the solid surface will hit the wear marks, forming a rough, slag hole-like outer surface.

VI. Pressure and explosion-proof structure of accessory positioner

1. Pressure-resistant packing formula:

(1) G1/2 interface at the electrical interface, one can be selected, and the unused interface is screwed down with blind plug.

(2) The actual connection thread of the pressure-resistant packing type should be greater than 5 pitches and locked with lock nuts.

(3) The wire is suitable for <$9 ~<$10 specifications and has suitable rubber seals.

(4) Rubber seals should use pressure sleeves to fully compress cables.

(5) Input signal +, -, do not make mistakes, wiring should be reliable, wiring screw M4, wiring cover inside and outside each has a grounding connector, you can choose one.

(6) After the input signal is connected, tighten the junction box and tighten the set screw M4.

(7) The positioner shell is equipped with terminal blocks, which should be reliably grounded during installation.

(8) The cable inlet of the positioner must be equipped with NEPSI approved AD105 DT-G1/2 cable inlet device.

2. Wiring:

(1) There are two G1/2 interfaces at the electrical interface, one can be selected, and the unused interface is screwed down with blind plug.

(2) Screw the sealing component into the interface with a threaded joint, and the actual connection thread should be greater than 5 pitches.

(3) When wiring, pay attention to avoid scratches on the wire skin and ensure that the wiring is correct.

(4) Input signal +, -do not make mistakes, wiring should be reliable, wiring screw M4, limit cover inside and outside each has a grounding connector, you can choose one.

(5) After the input signal is connected, tighten the junction box and tighten the firm screw M4.

3. Sealing barrier: Open the injection port of the sealing part and use asbestos sealing filler as a sealing barrier in the specified position. With the sealant injection port facing upward, screw the injection port firmly.

VII. Accessories Electrical valve positioner HEP-15 Fixed parameters:

HEP serieselectro-pneumaticvalve positioner is used with regulating valve, converting the output signal of regulating valve into the gas signal driving regulating valve, overcoming the friction force between packing box and valve stem, overcoming the unbalanced force of medium pressure difference on regulating valve core, improving the action speed of regulating valve, thus ensuring that regulating valve is correctly positioned according to the output signal of regulator.

Technical parameters:

Basic error:±1%(single action);±5%(double action)

Backlash:±1%(single action);±5%(double action)

Dead zone:±0.4%(single acting);±0.8%(double acting)

Rated stroke:0-(10-100)mm

0-(50-75-90)Angular stroke

Gas source pressure:0.14-0.55MPa

Input signal:4-20mA.DC;0-10mA.DC(separable)

Output pressure:0.02-0.5MPa

Air consumption: single action:450L/h(air supply0.14MPa)

Double action:360L/h(air supply0.55MPa)

Output characteristics: linear, equal percentage

Ambient temperature:-35~+60℃

-20~+60℃ (intrinsically safe)

Relative temperature: 10-90%

Input Yin: 4-20mA.DC300± 100(at 20℃)

0-10mA.DC1000± 300(at 20℃)

Air supply connector:M10 1. 5

Shell material: aluminum alloy

Appearance size: 203× 160× 105

Weight: 2.8kg

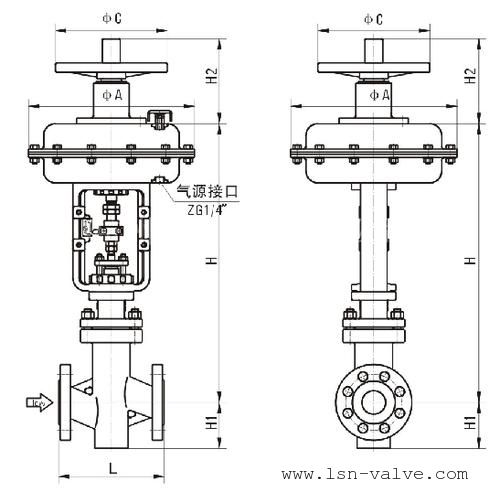

Eight,technical parameters:Nominal diameter DN(mm) 20 25 32 40 50 65 80 100 125 150 200 (10) (12) (15) (20) Rated flow coefficient KV straight line 1.8 2.8 4.4 6.9 11 17.6 27.5 44 69 110 176 275 440 690 equal percentage 1.6 2.5 4.0 6.3 10 16 25 40 63 100 160 250 400 630 Rated stroke L(mm) 16 25 40 60 Effective area of diaphragm Ae(cm2) 280 400 600 1000 Signal Range Pr(KPa) 20~100、40~200 Gas source pressure Ps(MPa) 0.14~0.4 inherent flow characteristic straight line, equal percentage inherent adjustable ratio 50 leakage allowed Hard seat: Class IV (10-4 valve rating) Soft seat: Class VI Nominal pressure PN(MPa) 1.0、1.6、4.0、6.4 Operating temperature t(℃) normal temperature type -20~200、-40~240、-60~250 heat dissipation type -40~450、-60~450 high temperature modification 450~560 low form -60~-100、-100~-200、-200~-250 The performance index of this product complies with GB/T4213-92 standard IX. Manufacturing requirements:Hangzhou Lianggong Valve Co., Ltd.(Sino-German cooperation) is located in the beautiful Fuchun River, adjacent to Hangzhou. The company was founded in 1996, registered capital of 41.8 million yuan, is a collection of scientific research and development, production, sales and service in one of the large control valve manufacturing enterprises, with strong technical force, advanced manufacturing equipment, perfect product testing facilities, and through the ISO9 OO1:2000 quality system certification, People's Republic of China special equipment manufacturing license (pressure pipe) number: TS2710D66-2011, British MOODY pressure parts CE certification, EU 3.1 material certification, EU industrial process control valve CE certification, CNNC qualified supplier, Sinopec first-class network supplier- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment.- Name(chinese)

- Name(English)

- Hangzhou Liangsheng Electric Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Fuyang City, Hangzhou, Zhejiang, China

- Nearby port

- Ningbo

Hangzhou Liangsheng Electric Co., Ltd.(formerly Hangzhou Lianggong Valve Co., Ltd.) was established in 1996. It is located on the bank of the Fuchun River with beautiful scenery, only 15 kilometers away from the "Paradise" Hangzhou and 20 kilometers away from the international airport. The transportation is very convenient. Our company is a professional manufacturer of automatic control valves. The company has strong technical force, excellent machining equipment, advanced production technology, and complete testing facilities and after-sales services. It has passed ISO9001: 2008 International Quality System Certification and People's Republic of China Special Equipment Manufacturing License-Pressure Pipeline-Control Valve Class A and is produced in accordance with the system, manufacturing license and EU CE certification. The product quality is reliable. The main products include: self-operated pressure regulating valves, nitrogen supply valves for nitrogen sealing devices, nitrogen relief valves, self-operated electrically controlled temperature regulating valves, self-operated steam pressure reducing and stabilizing valves, pneumatic membrane regulating valves, cylinder-type shut-off valves, pneumatic electric regulating ball valves, pneumatic membrane three-way dividing (closing) flow regulating valves, self-operated micro (differential) pressure regulating valves, GIQ-1.0W pneumatic high vacuum butterfly valves and many other series products. The company focuses on product development and research, constantly taps internal potential, and focuses on digesting and absorbing foreign advanced technology. Products are widely used in automatic control systems in petroleum, chemical industry, metallurgy, electric power, papermaking, light textile, food, refrigeration, pharmaceuticals, water supply and drainage and other industries. "Produce high-quality products, create high-quality management levels, and meet customer requirements", this is the commitment of Liangtai people. We are committed to advanced technology and high-quality products to help you reduce energy consumption and labor intensity; enhance safety performance; and provide a comfortable environment. -

Send your message to this supplier*From:*To:

Mr. Liming Cai

*Message:

Mr. Liming Cai

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.